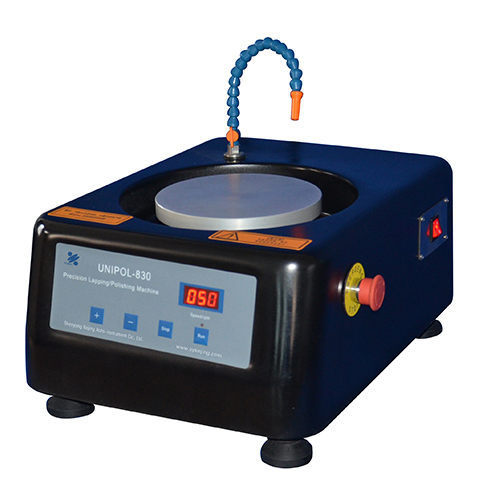

Macchina per rettifica e lucidatura di precisione per impieghi gravosi (8")

1. La velocità della macchina levigatrice-lucidatrice a posizione singola può essere regolata in continuo e la velocità di levigatura può essere controllata con precisione in base ai diversi materiali e alle esigenze di processo. La macchina levigatrice-lucidatrice aumenta la flessibilità operativa.

2. Durante il funzionamento della macchina per la molatura e la lucidatura, l'utente può regolare manualmente la pressione per controllare con precisione il processo di molatura e lucidatura.

3. Le lucidatrici manuali metallografiche possono utilizzare direttamente l'acqua del rubinetto per il raffreddamento durante la molatura e la lucidatura, il che semplifica il processo di raffreddamento, impedisce il surriscaldamento del campione e migliora l'efficienza della molatura.

- Shenyang Kejing

- Shenyang, Cina

- 10 giorni lavorativi

- 50 set

- informazione

Introduction of metallographic manual polishers:

UNIPOL-830 metallographic manual polishers is a manual grinding and polishing machine designed and developed by our company mainly for major colleges and universities, research institutes, and metallographic laboratories. Metallographic manual polishers can not only grind and polish metal materials, but also grind and polish other types of non-metallic materials, such as crystals, ceramics, glass, PCB boards, rock samples, mineral samples, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), refractory materials, composite materials and organic polymer materials. The grinding and polishing speed of metallographic manual polishers is infinitely adjustable, the pressure is manually controlled, the operation is simple, and the use is convenient. The metallographic manual polishers can be directly connected to tap water for cooling during the grinding process. The installation of sandpaper or polishing pad can be installed by pressing ring, and can be installed by magnetic adsorption. It is easy to load and unload, and different installation methods can be selected according to personal needs.

Main features of single position grinding polishing machine:

The single position grinding polishing machine can choose to place sandpaper and polishing pads by clamping ring or magnetic adsorption, which makes the operation more stable. Magnetic adsorption is mainly to overcome the shortcomings of pleating of traditional clamping polishing fabrics. The polishing fabric with pressure-sensitive adhesive is pasted on the grinding and polishing film, and then adsorbed on the magnetic sheet; secondly, the sandpaper and polishing pad of the single position grinding polishing machine are more convenient to replace.

Technical parameters:

Product Name | UNIPOL-830 Metallographic Grinding and Polishing Machine / Lapping Machine | |

Product Model | UNIPOL-830 | |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Power supply: AC110/230V 50/60Hz three-pole socket 10A. 4. Cooling water: The equipment is equipped with a water inlet and a water outlet, and you need to connect the tap water and drainage pipelines by yourself. 5. Air source: no requirement for standard equipment. 6. Workbench: It is recommended to use it on an operating table or desktop with a load-bearing capacity of more than 100kg. 7. Ventilation device: good ventilation environment, no special ventilation device requirements. 8. Auxiliary equipment (need to be purchased separately): Recommended: 1. SKCH-1 precision thickness gauge. 2. SZKD-2 automatic stirring dripper, SKZD-3 suspension dripper. 3. SKCS-1 blow dryer. | |

Main Parameters (Specification) | 1. Grinding polishing machine power supply port: AC110/220V conversion . 2. Total power: 180W. 3. Grinding polishing disc diameter: Φ203 mm. 4. Grinding polishing disc speed: 50-600rpm (adjustable). 5. Polishing disc station: 1 station. 6. Spindle drive motor: DC110V 165W. 7. Control mode: single chip microcomputer + button. Remarks: · Various grinding polishing discs, special fixtures, special parts, etc. can be customized according to user requirements. | |

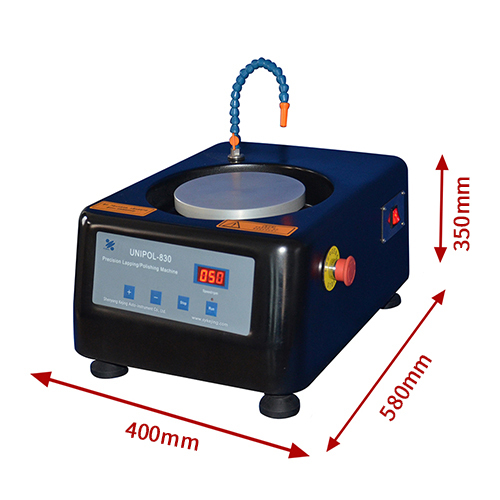

Product Dimension And Weight | 8. Product specifications: Dimensions: L400×W580×H350mm. Net weight: ≈24kg. |

|

Standard accessories:

No. | Name | Qty | Picture |

1 | Magnetic Sheet | 2 pcs |  |

2 | (Steel) Lapping Buffer Sheet | 5 pcs |  |

3 | Sandpaper | 8 pcs |  |

4 | Polishing Pad (Nubuck Leather, Synthetic Leather,) | 1 pcs each | |

5 | Diamond Polishing Paste | 1 pcs |  |

Optional accessories:

No. | Name | Functional type | Picture |

1 | SKZD-2 Slurry Feeder | (Optional) |

|

2 | SKZD-3 Slurry Feeder | (Optional) | |

3 | SKZD-4 Automatic Slurry Feeder | (Optional) | |

4 | SKZD-5 Slurry Feeder | (Optional) | |

5 | Magnetic Resin Diamond Lapping Plate | (Optional) | |

6 | UNIPOL-01 Type TEM Wedge Grinding And Polishing Fixture | (Optional) |  |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

The company is equipped with an experienced and skilled professional team that can not only answer various questions encountered by customers during use, but also provide customers with customized technical support and solutions. Whether it is a new customer who is first exposed to the product or an old customer with rich experience, you can find the help and support you need here. Whether you want to understand the operating procedures of the product or want to get personalized technical support, we will serve you wholeheartedly. We hope that you can provide valuable opinions and suggestions to help us further improve and enhance.