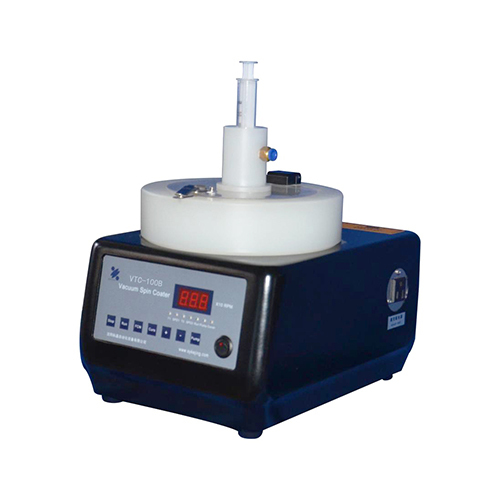

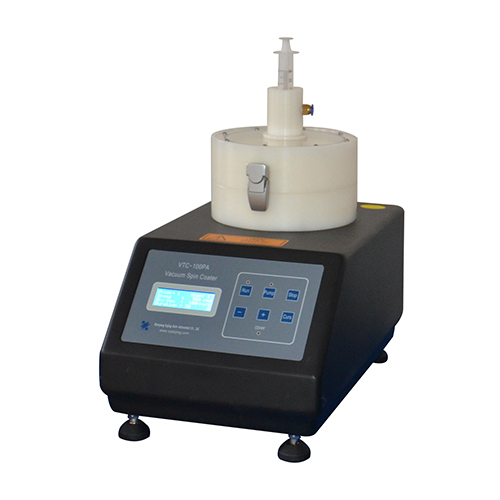

Spalmatrice centrifuga compatta (8.000 giri/min, wafer max. da 4") Design a mandrino basso

La spalmatrice centrifuga sottovuoto VTC-100B è una versione aggiornata della spalmatrice centrifuga sottovuoto VTC-100. Il coperchio superiore è ripiegabile per l'apertura e la chiusura ed è dotato di un blocco di sicurezza. Allo stesso tempo, svolge la funzione di protezione in caso di apertura accidentale del coperchio per garantire una maggiore sicurezza dell'operatore.

- Shenyang Kejing

- Shenyang, Cina

- 10 giorni lavorativi

- 50 set

- informazione

Introduzione al prodotto

Il VTC-100B Vacuum Spin Coater è una versione aggiornata del VTC-100, progettato per applicazioni di spin coating. È caratterizzato da un funzionamento semplice, una facile pulizia e un design compatto, che lo rendono ampiamente utilizzato nei laboratori di università e istituti di ricerca per i processi di rivestimento di film sottili.

L'apparecchiatura è dotata di serie di tre mandrini a vuoto di diverse dimensioni, consentendo agli utenti di scegliere il mandrino più adatto in base alle dimensioni del campione. Durante il funzionamento, il campione viene fissato sul mandrino tramite aspirazione a vuoto. Il VTC-100B utilizza un controllo programmabile a due stadi della velocità di rotazione, con un tempo di esecuzione massimo di 600 secondi per fase, e include una funzione di conto alla rovescia durante il funzionamento.

Il coperchio superiore è progettato con una struttura di apertura a cerniera, dotata di un fermo di sicurezza e include una funzione di protezione contro l'apertura del coperchio per garantire ulteriormente la sicurezza dell'operatore. Sfruttando la rotazione ad alta velocità del motore, il VTC-100B ricopre uniformemente materiali viscosi come gel e soluzioni sulla superficie del campione.

Caratteristiche principali

1. La velocità è controllata da un programma a due fasi: la colla viene iniettata nella prima fase a bassa velocità e la colla viene livellata nella seconda fase ad alta velocità.

2. Il campione viene fissato tramite adsorbimento sotto vuoto, che è facile da usare e comodo per prelevare e posizionare il campione.

3. Struttura in alluminio pressofuso, funzionamento stabile e basso rumore

4. La regolazione della velocità è controllata da un computer a chip singolo con elevata anti-interferenza e la velocità è molto stabile nell'intervallo da 1000 a 8000 giri/min.

5. Con funzione di protezione contro l'apertura del coperchio

6. Con funzione di conto alla rovescia

7. Viene adottata una struttura (in cui la superficie del mandrino a vuoto è più bassa della camera) per garantire che il substrato non venga espulso dalla camera e/o ferisca lo sperimentatore nel caso in cui il campione non sia saldamente attaccato alla piastra del campione.

TtecnicoPparametri

Nome del prodotto | VTC-100B Vacuum Spin Coater | |

Modello del prodotto | VTC-100B | |

Condizioni di installazione | 1. Temperatura e umidità: 10–85% RH (a 25℃, senza condensa); Temperatura: 0–45℃. 2. L'apparecchiatura deve essere posizionata lontano da forti fonti di vibrazioni e gas corrosivi. 3. Acqua: non richiesta. 4. Alimentazione: monofase AC220V 50Hz 10A. 5. Aria: pressione negativa del vuoto (pompa a vuoto) con una portata di estrazione non inferiore a 70 L/min. 6. Banco da lavoro: consigliato 800 × 600 × 700 mm, capacità di carico superiore a 100 kg (è preferibile un tavolo in cemento solido). 7. Ventilazione: Nessun requisito particolare. | |

Parametri principali (Specifiche) | 1. Interfaccia di alimentazione: presa di corrente con fusibile, AC220/110V 50/60Hz, specifiche del fusibile 10A, φ5×20mm. 2. Potenza totale: ≤150W. 3. Supporto per campioni (mandrino a vuoto): mandrini a vuoto in polipropilene, Φ25 mm, Φ50 mm e Φ100 mm (uno ciascuno). 4. Modalità di funzionamento: rotazione antioraria con due fasi di funzionamento. 5. Velocità di rivestimento rotante: velocità SPD1: 500–8000 giri/min (effettivi) Velocità SPD2: 500–8000 giri/min (effettivi). 6. Tempo di rivestimento a centrifuga: tempo T1: 1–600 s (effettivo); Tempo T2: 1–600 s (effettivo). 7. Stabilità della velocità: ±1%. 8. Sistema di controllo: microcontrollore PCB con controllo tramite pulsante e display digitale a tubo. | |

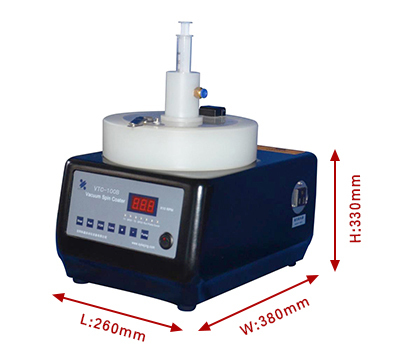

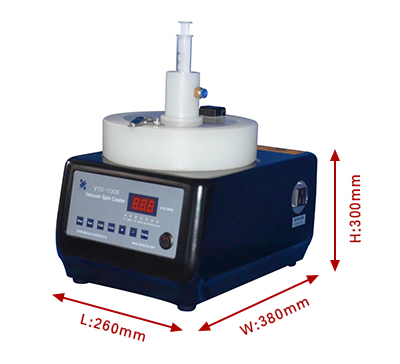

9. Specifiche del prodotto: · Dimensioni: 260 mm × 380 mm × 300 mm · peso: 20 kg |

| |

SstandardUNaccessori

NO. | nome | quantità | immagine |

1 | Mandrino a vuoto (PP,Ø25mm,Ø50mm,Ø100mm) | 1 pz ciascuno | |

2 | Iniettore/Siringa | 1 pz | |

3 | Pompa per vuoto senza olio | 1 pz |

|

ILfacoltativoUNaccessori

NO. | nome | tipo funzionale | immagine |

1 | Mandrino a vuoto speciale (PTFE, lega di alluminio) | (opzionale) | - |

2 | Mandrino micro-dimensionato | (opzionale) |

|

3 | Filtro (per pompa a vuoto) | (opzionale) | - |

4 | Pipetta (prodotta in Cina) | (opzionale) |

|

5 | Pipetta (importata) | (opzionale) |

|

6 | Piastra di serraggio del campione | (opzionale) | - |

Garanzia

Garanzia limitata di un anno con supporto a vita (escluse le parti arrugginite dovute a condizioni di conservazione inadeguate)

Logistica